“If you are unhappy with the market that you are in, you must create a new market”.

Joseph Kufner, the father of Dominik Kufner was saying this often, in the years when Dominik was a young man, learning this business. Dominik observed many people who thought that this statement sounds nice, but that it is also quite impossible. “How can you change a market to fit your own needs”? The answer was simple – develop new products.

The Kufner family has done exactly that, not only once but several times. Each time they did, they secured success in their generation.

1800 BARTHOLOMEUS KUFNER

In the 1800’s Dominik’s great-great-grandfather was the first to connect his factory to the Munich power grid, and switch to electrical power and light. Automated production created products which became leading worldwide. A new market was created.

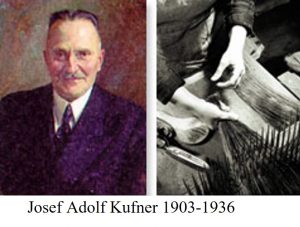

1900 JOSEF ADOLF KUFNER

In the early 1900’s Dominik’s great grandfather invented horsehair interlinings, which quickly replaced thick felt interlinings. This completely changed the men’s tailored clothing industry. Again, a new market was created.

1930 DR. ING. GEORG KUFNER

In the 1930’s Dominik’s grandfather invented twisted horsehair interlinings. In the years thereafter, the single drawn horsehair products were fully replaced on the world market. Again, a new product had created a new market.

1960 GEORGE AND JOSEPH KUFNER

In the 1960’s Dominik’s father and uncle invented fusible interlinings. In a bold and crazy move a large machine – that was to become known as a fusing press – was installed in the ballroom of a luxury hotel in Munich – and the invention was announced. In the years that followed, such fusing presses were installed in clothing factories all over the world, and non-fusible interlinings completely disappeared. Once again, a new product has changed an industry.

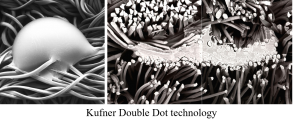

1970 KUFNER DOUBLE DOT TECHNOLOGY

In the 1970’s they invented the double-dot coating technology, to radically reduce fusing problems. Thirty years later – after our patents expired – also this was copied all over the world and is today still an industry standard.

1990 DOMINIK, JOSEPH AND GEORGE KUFNER

In the 1990’s, Dominik invented elastic fusible interlinings, which fully adapted to the behaviour of outer fabrics. A new level of softness and safety was now possible, which revolutionized the fashion industry worldwide. All remaining fusing problems disappeared, and fashion could become softer than ever before. Today, it is hard to find any non-elastic interlinings anywhere in the world. Again, there was a new market.

In going door-to-door for the better part of 15 years, Dominik presented many such game changing inventions to clothing companies all over the world. He could see the initial hesitance and the slow transition that followed. He learned that product developments are almost always challenged with initial resistance.

But in this time, he also learned that when a new product makes enough sense, it will eventually make its way into the market – and when that happens, the market can eventually change permanently. So, we now look back and recognize that Dominik’s father was right. If the development is good enough, even small to medium sized businesses can “create their own markets”.

2009 DOMINIK KUFNER & SOFIA CINEL

In 2009 the Kufner company was sold. Dominik felt that there was little left to develop in the field of interlinings and decided to leave the company. He started a new business, together with his partner, Sofia Cinel. They created the Kufner-Cinel company, which we then renamed to KC. The mission of the company was to innovate in the fashion industry, but this time the developments were unbound by the limitations of what their own factories could produce.

They spent the next several years developing new wearable technologies, and the components needed to make them possible. In 2016 they created an office in Shenzhen, where most of the developments were then realized in bulk production. As of 2017 they have been supplying the clothing industry with the first innovations.

2021 TODAY

Today, KC has established a wide range of new technologies which are used by leading fashion brands all over the world. Again, a new market has been created.

Today, jackets can absorb odor molecules. Hats can be earphones. With flexible lithium batteries, belts can become powerbanks. Silver pockets can protect credit cards from illegal scanners and decontaminate their content from bacteria and viruses. Jackets can electrically warm or cool the body. Buttons with NFC chips can induce smartphone functions. Handbags, wallets, and notebook covers can recharge smartphones. There are many others and many more to come…